Novatech branded products are designed, manufactured and calibrated in-house allowing for a bespoke service from start to finish.

Load Cells Offer Precision and Efficiency for Manufacturing and Production

Load cells are used throughout all aspects of modern manufacturing and production process, leading to improved production quality, lower costs and greater efficiency.

The output from a single load cell could be used to inform a control system when one action can start, the rate at which the action can be carried out, when the action should stop and when the next action can follow on. This allows much of the process to be performed at high speed, with coarse resolution, and slow down when close to a threshold, affording a mix of speed and precision that would not be possible with a simple on/off electrical limit switch.

In most manufacturing businesses, where profit margins are dependant on efficient, high- volume production, any time savings that can be achieved are extremely valuable.

Load cells can also ensure that the final product meets with the relevant regulatory standards. For example, accurate dosing of ingredients in medicines, or guaranteeing that products sold by weight cannot fall short of customer expectations.

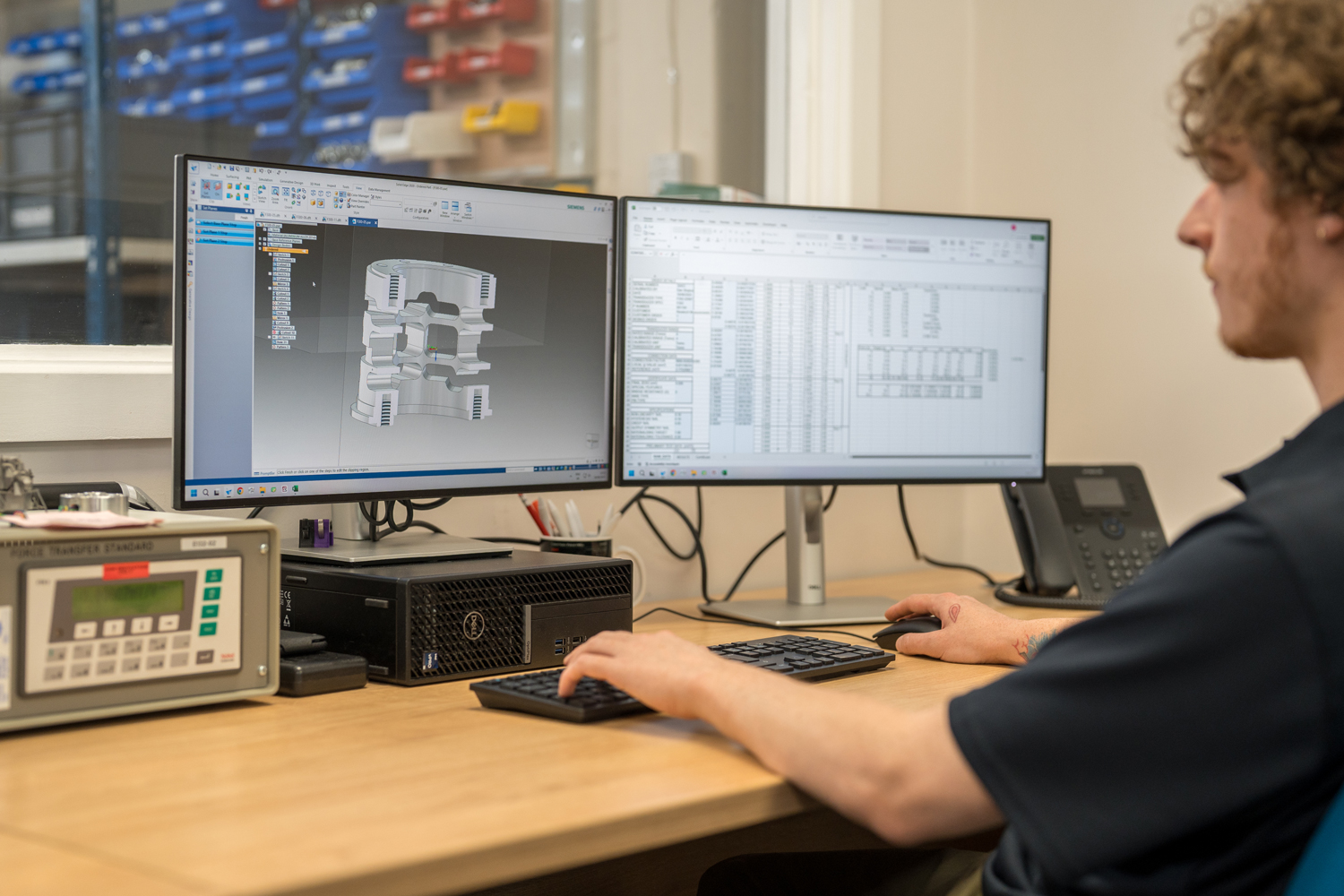

Experienced Design Team Providing Tailored Solutions and Retro-fit Options

While the benefit of force measurement and control feedback is clear, load cells are not always incorporated into machinery by the original equipment manufacturer. This may be

due to perceived limitations on space, where an ‘off-the-shelf’ solution could not be found. However, a tailored solution may be possible using a bespoke load cell.

This could be either; one designed specifically to fit the space available, or even one replacing an existing part with a copy in the form of a load cell with the same dimensions. Both options potentially save vast sums of money by circumventing the need to redesign or modify the machine.

We can also offer like for like replacements for obsolete items where the original part cannot be found. In most cases, load cells can be successfully retro-fitted to existing machinery.

Our design team share over 40 years of load cell design experience and have provided thousands of bespoke designs during their time at Novatech. We price each job fairly, based on material and labour, and do not impose minimum order quantities. A bespoke solution may not cost much more than a standard device and offers greater time saving and efficiency within the customer’s own design process.

Versatility and Adaptability Providing Solutions to all Industry Sectors

With complete control over the design, manufacture and calibration of our products, we can adapt our load cells to be suited to nearly all environments and uses. This means that even a standard load cell design can be made suitable for a wider variety of end user applications, making Novatech products some of the most versatile on the market.

We have a comprehensive stock of material and components and can rapidly source new components, allowing us to make appropriate selections for elevated temperatures, vacuum or submersible applications, chemical resistance or radiation.

Our machine shop houses a large variety of modern CNC lathes and milling centres, including two 4-axis semi-automated machines. Production times are tightly scheduled and, even with customisation options, our lead times are a number of weeks rather than months.

With the benefits provided by our experienced team and unparalleled service, Novatech have provided load cells for a wide variety of applications including;

- Mining / quarrying and material processing

- Forging, rolling and sintering

- Manufacturing and heavy industry

- Bulk weighing and process control

- Die cutting and hydraulic press applications

- Additive manufacturing / 3D printing

- Construction / civil engineering

- Pulp and paper mills

- Robotics and animatronics

- Automotive production and testing

- Motorsport aerodynamics and performance

- Aerospace including low-outgassing vacuum applications

- Marine and other submersible applications

- Nuclear and renewable energy generation

- Medical devices, research and pharmaceuticals

- Quality assurance and safety testing

If you have an application that requires precision force and/or torque measurement, please speak to one of our engineers, who provide a direct point of contact and are always happy to help. Please be advised that they will require detailed information about the function that the load cell needs to perform and the environment in which it will be placed. We appreciate that this may involve needing to share sensitive data and we are of course happy to sign non-disclosure agreements as required.

Our engineers can offer any level of involvement in your project that you may require and will work closely with you or the end user to ensure we collectively achieve the optimum solution. There is no need to limit your thinking to our standard product catalogue. We encourage you to contact us to discuss your requirement and to ensure you end up with the right tool for the job.